MOST COMMON APPLICATIONS OF ALUMINUM EXTRUSION

Aluminum Extrusion is All Around

Aluminum extrusion transforms aluminum alloy into an extraordinary variety of products for consumer and industrial markets. Aluminum extrusions have many uses in the electronics, automotive, mass transit, bridge decking, telecommunications, solar/renewable energy industries, and more.

Many of those fabrications, , use extruded aluminum section. As you may have noticed, we’re fans of this material. That’s because it simplifies fabrication assembly while improving strength and stiffness. It’s also lightweight, corrosion-resistant and good-looking. (You can polish it to a shine, anodize it, coat it or paint it.)

These properties make it ideal for a wide range of applications. In fact you might be surprised to learn just how many uses for extrusion there are.

Common Applications

Producing a ranked list would mean debating definitions and whether to use tons, yards or dollars. We argue enough as it is, so we’ve just gone with an alphabetical list drawn from what we know.

Architecture

This category of applications ranges from railings and balustrades to building facades and bleachers. As extruded aluminum section is stiff and lightweight it’s ideal for applications like canopies where the structure can’t weigh much but must handle a load. (High stiffness means you need less of it, which translates to more weight-saving.) It also looks attractive uncoated and as it doesn’t rust, exposure to rain isn’t a concern.

Automotive

Aluminum is also ideal for automotive applications like trailers. Keeping trailer weight low lets your tow vehicle devote more of its torque to hauling the stuff you actually want to shift and less to moving the trailer itself. It’s also used extensively in RV’s for the same reason, plus it won’t rust and can be polished up to look almost like chrome, so it’s good for decoration too.

Display equipment

Almost every stand you’ve ever seen at a trade show or exhibition was constructed with a great deal of extruded material. That’s because extruded section can be designed so pieces interlock, making assembly quick and easy. It’s easy to move around too, and it can be finished any number of ways for an attractive and durable appearance.

In the same vein, point-of-sale displays and display cabinets are other examples of aluminum extrusion used for display equipment.

Framing

By using inserts to join lengths of extrusion pieces it’s easy to build various kinds of frames. Picture frames might be the most obvious, but a rapidly growing application is frames to hold solar panels. As these are often roof-mounted, aluminum’s lightweight, corrosion-resistant nature makes it the ideal material.

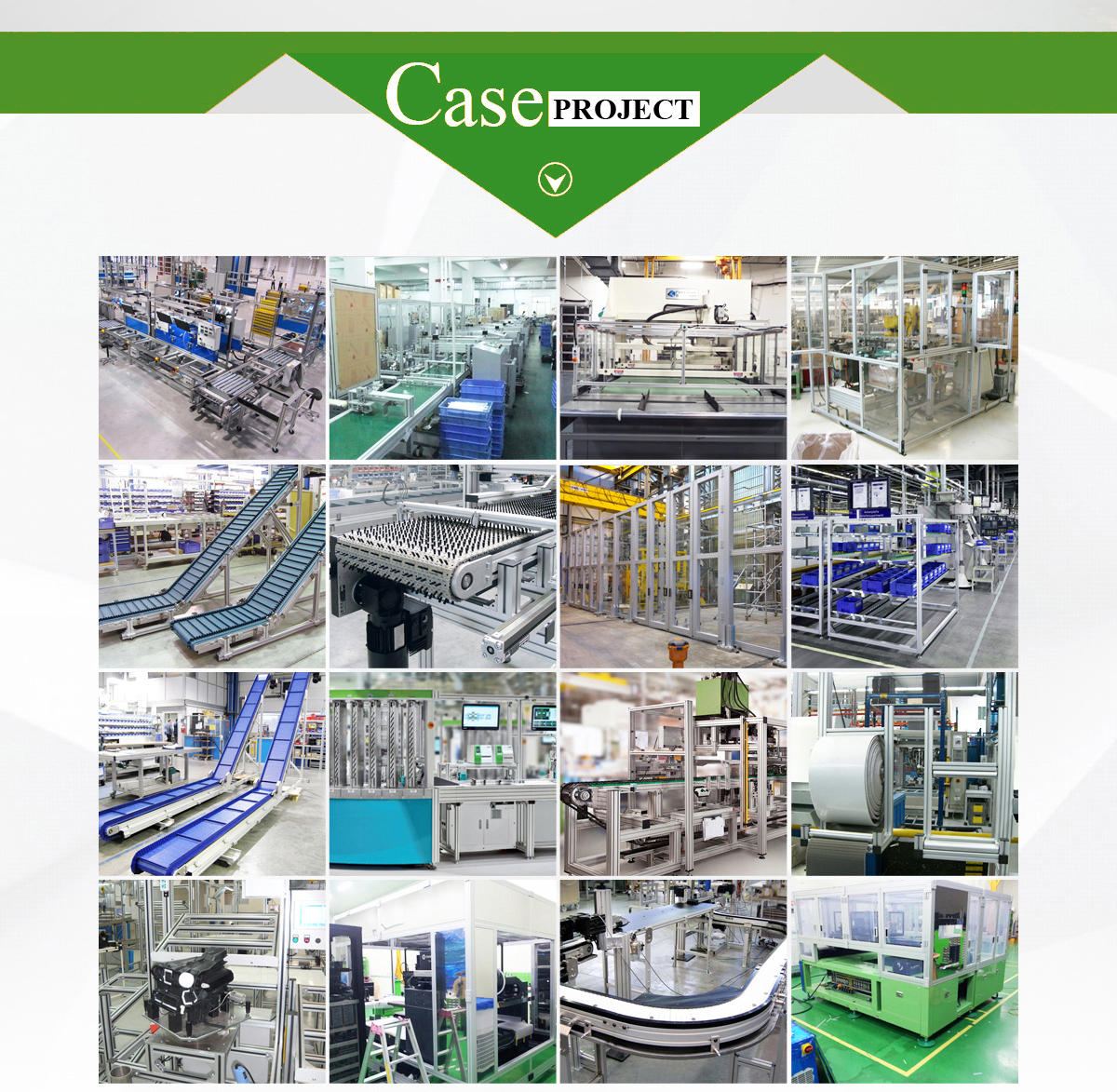

Industrial

Walk through any factory, (ours included,) and you’re almost guaranteed to see aluminum extrusion being put to work. It’s the material of choice for equipment like workbenches, inspection tables and carts because it’s easy to cut and drill, lightweight yet stiff, and good value-for-money. It also has the added attraction of being extendible: if a workbench needs modifying that’s quickly done.

In the same factories you’ll often also see extrusion for machine guards. It goes together quickly and can be fitted with Lexan panels for a clear view while protecting people working nearby.

Thinking about uses for aluminum extrusion

If you think about metal fabrications as much as we do you’ll spot them everywhere. Take a closer look and you’ll see many were built using aluminum extrusion. It really is the most extraordinarily versatile material, and that’s why we like working with it.

Please feel free to contact us by info@roc-aluminum.com for more detailed info if you’re interested in this Aluminum profiles.